Foil Assist Diy Battery Box Fairing Propeller

We produce the Battery Box, Fairing, and Propeller for Foil Assist Diy. As a more than 10-year-old surfing product manufacturer, we provide customized service for many surfing brands and have extensive experience in the areas of hydrofoil, foilboard, paddles, and parts. Like this foil assist kit, they are made of high-quality aluminum (titanium alloy is also Available) and processed by the CNC machine.

If you are going to set up a full set for your brand or foil assist diy, we should be your reliable manufacturer to realize your design. Now, contact us to get more details.

Available For Foil Assist Diy

- Product: Battery Box, Fairing, Propeller, or any metal parts

- Material: aluminium alloy, titanium alloy, carbon fiber composites, fiberglass composites

- Manufacturing Process: CNC, Autoclave Molding, Compression Molding

- Service: OEM, ODM

- Sample: Available

- Price: Send us your requirements

More Foil Assist Diy Parts Details

Why Choose Our Foil Assist Parts?

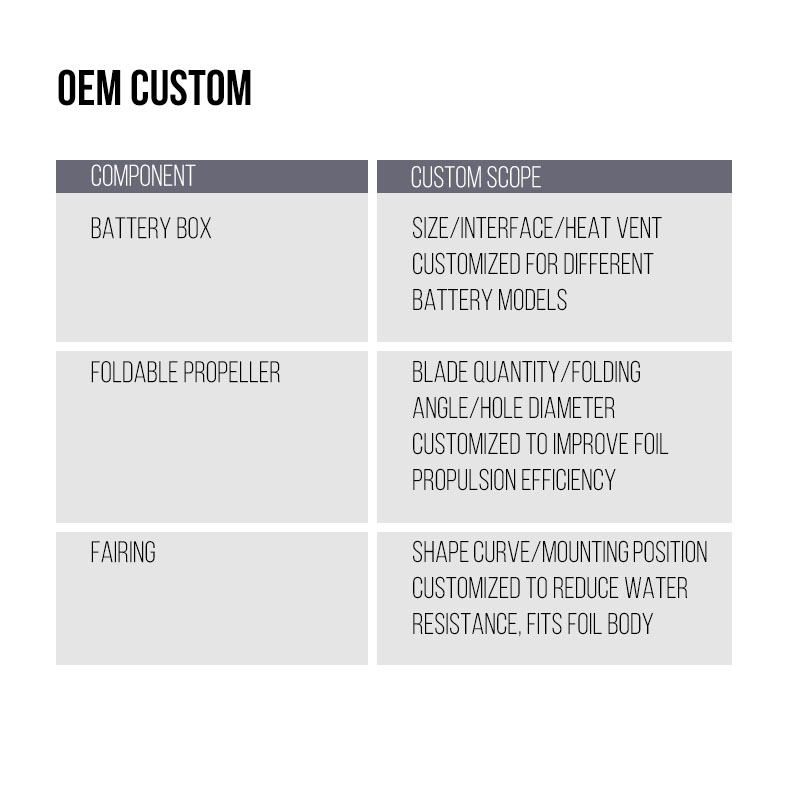

Choosing Unity Sports means choosing performance, reliability, and customization. Our Foil Assist components are built with precision engineering and premium materials to meet the demanding needs of electric hydrofoil systems. Each part — from the battery box to the propeller — is optimized for lightweight strength, superior corrosion resistance, and efficient power delivery on the water. With over 10 years of experience in hydrofoil and e-surf manufacturing, we provide OEM and ODM services that ensure perfect compatibility, consistent quality, and tailored design for your brand..

Customized

Foil Assist Parts Customization Process

At Unity Sports, we provide a full OEM & ODM customization service for Foil Assist components such as Battery Boxes, Fairings, and Propellers.

Our process includes but is not limited to the following steps:

-

Design Submission – Send us your design drawings or 3D files for initial evaluation.

-

Technical Evaluation – Our engineering team will review the design and materials, then hold an internal meeting to determine the best production solution.

-

Quotation & Proposal – We will provide a detailed production plan, estimated lead time, and cost proposal for your approval.

-

Sample Production – Once confirmed, we will start producing the prototype or sample according to your specifications.

-

Testing & Validation – The sample will be tested for fit, performance, and durability. Adjustments can be made if necessary.

-

Mass Production – After sample approval, we proceed to full-scale production with strict quality control and inspection standards.

We ensure every project is handled with precision, transparency, and a focus on long-term partnership.

Battery Box, Fairing, and Propeller For Foil Assist DIY

Our Foil Assist Battery Box, Fairing, and Propeller are engineered for performance, precision, and durability in marine environments. Each component is designed to deliver optimal hydrodynamics, corrosion resistance, and structural strength — ensuring a reliable and efficient foil assist experience.

Material Options:

-

6061-T6 Aluminum Alloy: Lightweight yet extremely strong, precision CNC-machined with a density above 17 g/cm³. This marine-grade alloy offers excellent strength-to-weight ratio, good heat dissipation, and high resistance to deformation — making it ideal for structural parts and housings.

-

Titanium Alloy: Perfect for saltwater applications, titanium provides outstanding corrosion resistance and superior longevity even in the harshest marine conditions. It combines high mechanical strength with ultra-low density, ensuring performance with minimal maintenance.

-

Composite Materials (Carbon Fiber / Fiberglass): For the ultimate lightweight performance, our composite versions are crafted using advanced autoclave or vacuum infusion processes. These parts offer excellent rigidity, vibration damping, and a premium surface finish while significantly reducing overall weight.

Key Features:

-

High-precision CNC or composite molding fabrication

-

Excellent corrosion and fatigue resistance

-

Customizable designs for OEM/ODM production

-

Compatible with multiple foil assist systems and power setups

-

Optional carbon or titanium reinforcement for extreme conditions

Applications:

Ideal for Hydrofoil Foil Assist propulsion systems, these components are widely used by professional riders and premium surf brands worldwide. Whether you’re building a DIY foil assist or designing a commercial-grade electric surf system, Unity Sports delivers one-stop production from concept to finished product.

If you also want the hydrofoils, please click the link to a check.