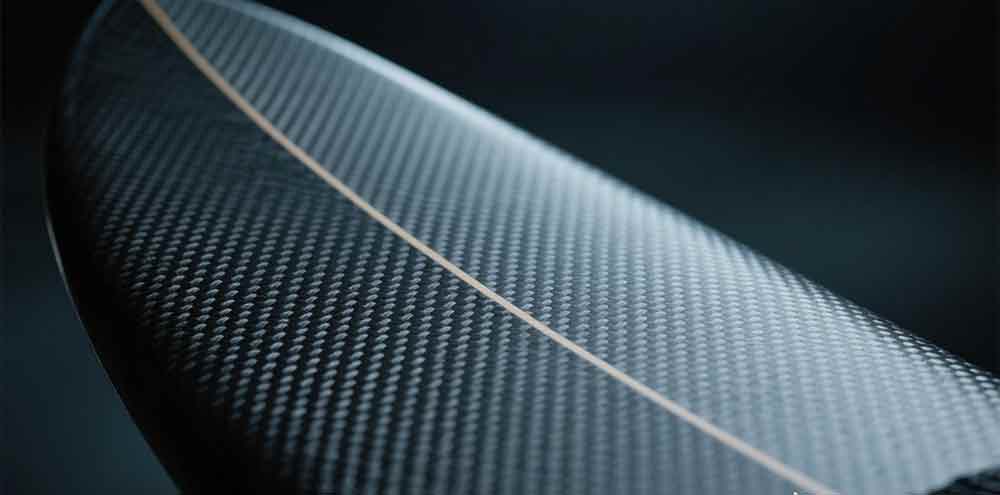

Whether buying a high modulus carbon fiber mast is worth it depends on your individual needs and budget. But as a 10+ years experience composite manufacturer in the surfing industry, we have reach experience on different modulus levels about hydrofoil masts. We will provide some factors to help you if it is worth it. Before estimating its value we should know more about it.

What is the Modulus of Carbon Fiber?

The modulus of carbon fiber, also known as its Young’s modulus or elastic modulus, typically ranges from about 230 to 441 gigapascals (GPa). This modulus represents the stiffness of the carbon fiber material, indicating its resistance to deformation under stress. Carbon fiber is renowned for its exceptionally high modulus, making it one of the stiffest materials available. Its high modulus, combined with its low weight, makes carbon fiber an ideal choice for applications where strength, rigidity, and lightweight properties are crucial, such as aerospace, automotive, sporting goods, and other high-performance industries.

Standard Modulus Carbon Fiber

Standard modulus carbon fiber typically has a modulus of elasticity ranging from about 230 to 265 gigapascals (GPa). It offers a good balance of stiffness, strength, and cost-effectiveness. Standard modulus carbon fiber finds applications in various industries, including aerospace, automotive, sporting goods, and industrial components.

Intermediate Modulus Carbon Fiber

Intermediate modulus carbon fiber has a higher modulus of elasticity compared to standard modulus, typically ranging from about 265 to 320 GPa. It provides increased stiffness and strength compared to standard modulus carbon fiber. Intermediate modulus carbon fiber is often used in applications requiring improved performance, such as high-performance sporting goods, aerospace components, and specialized industrial equipment.

High Modulus Carbon Fiber

High modulus carbon fiber possesses even higher stiffness, typically ranging from 320 to 440 GPa. It offers exceptional stiffness and strength, making it suitable for applications demanding superior performance and lightweight properties. High modulus carbon fiber is utilized in advanced aerospace structures, high-performance racing vehicles, premium sporting goods, and specialized industrial applications.

Ultra High Modulus Carbon Fiber

Ultra high modulus carbon fiber represents the highest stiffness among the four types, typically exceeding 440 GPa. It provides unparalleled stiffness and strength characteristics, offering top-tier performance. Ultra high modulus carbon fiber is employed in extremely demanding applications where maximum performance and weight savings are critical, such as advanced aerospace components, high-performance sports equipment, and specialized industrial machinery.

Carbon Fiber Modulus Sheet

| DF | Materials | Tensile Modulus(GPa) | Tensile Strength(GPa) |

| Standard Modulus

(<265GPa) (also known as “High Strength’) |

T300 | 230 | 3.53 |

| T700 | 235 | 5.3 | |

| HTA | 238 | 3.95 | |

| UTS | 240 | 48 | |

| 34-700 | 234 | 45 | |

| AS4 | 241 | 4 | |

| T650-35 | 241 | 4.55 | |

| Panex 33 | 228 | 3.6 | |

| F3C | 228 | 3.8 | |

| TR50S | 250 | 4.83 | |

| TR30S | 234 | 4.41 | |

| Intermediate Modulus

(265-320GPa) |

T800 | 294 | 5.94 |

| M3OS | 294 | 5.49 | |

| IMS | 295 | 4.12/5.5 | |

| MR40VMR50 | 289 | 4.415.1 | |

| IMG/IM7 | 303 | 5.1/5.3 | |

| IM9 | 310 | 5.3 | |

| T650-42 | 290 | 4.82 | |

| T40 | 290 | 5.65 | |

| High Modulus

(320-440GPa) |

M40 | 392 | 2.74 |

| M40J | 377 | 4.41 | |

| HMA | 358 | 3 | |

| UMS2526 | 395 | 4.56 | |

| MS40 | 340 | 4.8 | |

| HR40 | 381 | 4.8 | |

| Uitra High Modulus

(440GPa+) |

M46J | 436 | 4.21 |

| UMS3536 | 436 | 4.5 | |

| HS40 | 441 | 4.4 | |

| UHMS | 441 | 3.45 |

As can be seen from the above information, different modulus levels will affect the tensile strength and thus the product strength. However, whether it is worth buying a high-modulus hydrofoil mast with high strength depends mainly on your application, budget, and other factors.

The High Modulus Carbon Fiber Mast

A high modulus carbon fiber mast is a critical component of hydrofoil systems used in water sports such as kiteboarding, windsurfing, and surfing. If you are a serious windsurfer or kitesurfer who is looking for the best possible performance, then a High Modulus Carbon Fiber Mast may be a worthwhile investment. However, if you are a casual rider or you are on a budget, then a traditional mast may be a better option.

Evaluating Performance Benefits

Enhanced Stability and Control: High modulus carbon fiber masts provide superior stability, reducing vibration and enhancing control during maneuvers. The rigidity of the material minimizes deflection, translating to precise handling and improved performance in varied conditions.

Optimized Efficiency: The lightweight nature of carbon fiber reduces mass aloft, optimizing the hydrofoil’s efficiency. This results in reduced drag, allowing for smoother transitions between foiling and riding, ultimately enhancing speed and maneuverability on the water.

Durability and Longevity: Carbon fiber’s inherent resistance to corrosion and fatigue ensures longevity, making it a durable investment for hydrofoil enthusiasts. Its ability to withstand harsh marine environments prolongs the mast’s lifespan, offering reliability over extended periods of use.

Considering Cost and Investment

While the benefits of a high modulus carbon fiber mast are undeniable, it’s essential to weigh the investment against personal preferences and budgetary constraints. While initial costs may be higher compared to alternative materials, the long-term performance and durability justify the expenditure for avid hydrofoil enthusiasts seeking uncompromised performance and reliability on the water.

Conclusion

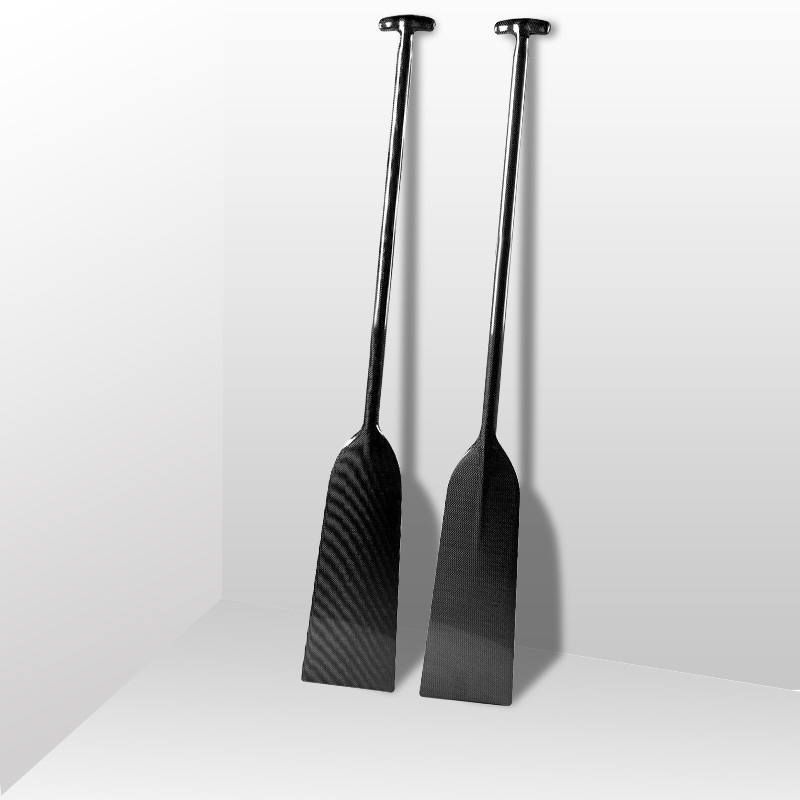

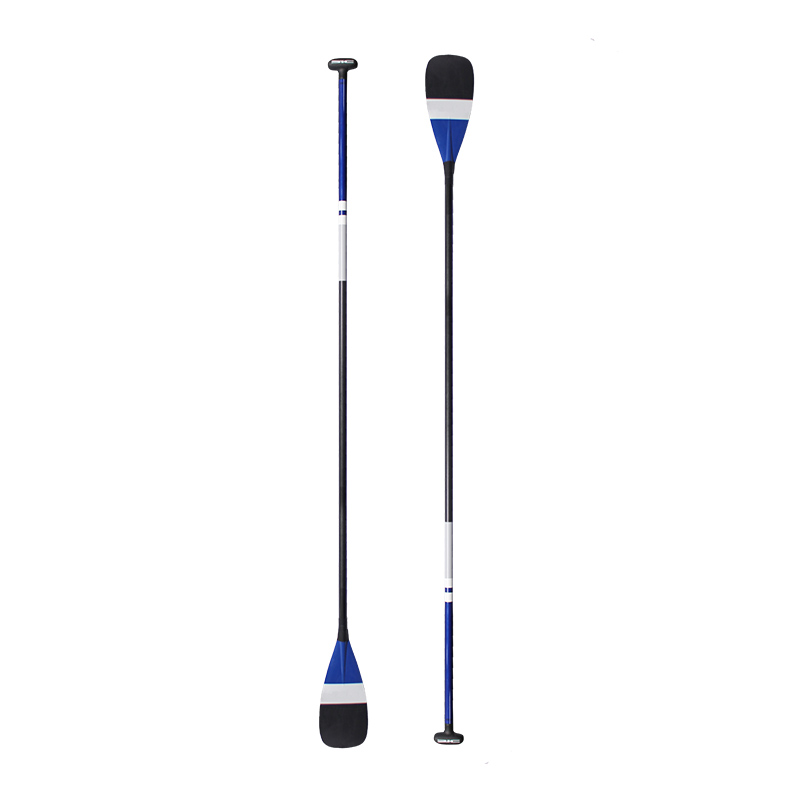

In conclusion, the decision to invest in a high modulus carbon fiber mast hinges on a balance of performance expectations, budget considerations, and personal preferences. With its unparalleled strength, lightweight construction, and longevity, it represents a worthwhile investment for discerning hydrofoil enthusiasts committed to pushing the boundaries of performance on the water. If you want to custom a different level modulus of carbon fiber mast, hydrofoil, foil board, or paddles, welcome to contact us for more details.