Foam surfboard is an important part of surfing sport. Whether you’re a seasoned pro or a newbie ready to catch your first wave, choosing the right surfboard is crucial. Among the myriad options available, foam surfboards stand out for their versatility and suitability for various surfing conditions. In this comprehensive guide, we’ll delve into the world of foam surfboards, covering everything from what they are and their applications to maintenance, storage, and how they differ from other types of surfboards. Plus, we’ll help you find the perfect foamie and where to buy it.

What is a Foam Surfboard?

A foam surfboard, often referred to as a soft-top surfboard and foamie, is a type of surfboard characterized by its soft foam deck and a hard plastic or fiberglass bottom. These boards are designed to provide a safe and forgiving experience for surfers of all levels, making them an excellent choice for beginners and those seeking a relaxed and fun ride.

Three main components of foamie

- Foam Core: The core of a foam surf board is made of soft, lightweight foam material. This foam provides buoyancy, making it easier for surfers to paddle, catch waves, and maintain stability in the water. Some foam cores may also include wooden stringers for added strength and rigidity.

- Soft Foam Deck: The deck, or top surface, of the foamie is covered with a layer of soft foam. This foam deck provides a comfortable surface for surfers to stand or lie on. It is designed to be forgiving and reduce the risk of injury during falls or collisions, making foam surfboards an excellent choice for beginners and surf schools.

- Bottom: The bottom of the foam surfboard is constructed from a more rigid material, often plastic or fiberglass. This hard bottom enhances the board’s durability and allows it to glide smoothly on the water, providing better performance than if the entire board was made of foam.

These parts constitute the basis of the board. In addition to these components, the fins and fin box, leash and leash plug, handle, traction pad, hydrofoil, and so on. Which is depend on the board type and application.

The Application of the Soft-top Surfboard

Foam surfboards have a wide range of applications, making them a versatile choice for surfers with different skill levels and preferences.

- Beginners: Foam surf boards are ideal for beginners surfing. Their buoyancy and stability make it easier for new surfers to catch waves and gain confidence in the water. The forgiving nature of foam boards reduces the risk of injuries during the learning process.

- Surf Schools: Many surf schools use foam surf boards for teaching purposes. The safety features of these boards make them suitable for instructing beginners, and their durability ensures they can withstand heavy use.

- Casual Surfing: Even experienced surfers enjoy riding soft-top surfboard for a more relaxed and fun experience. These boards are perfect for small, slow waves or simply cruising along the waves.

- Family Surfing: Foam surf boards are excellent for family outings. They accommodate surfers of different skill levels and ages, making them a versatile choice for a day of fun at the beach.

The Difference with Other Types of Surfboards

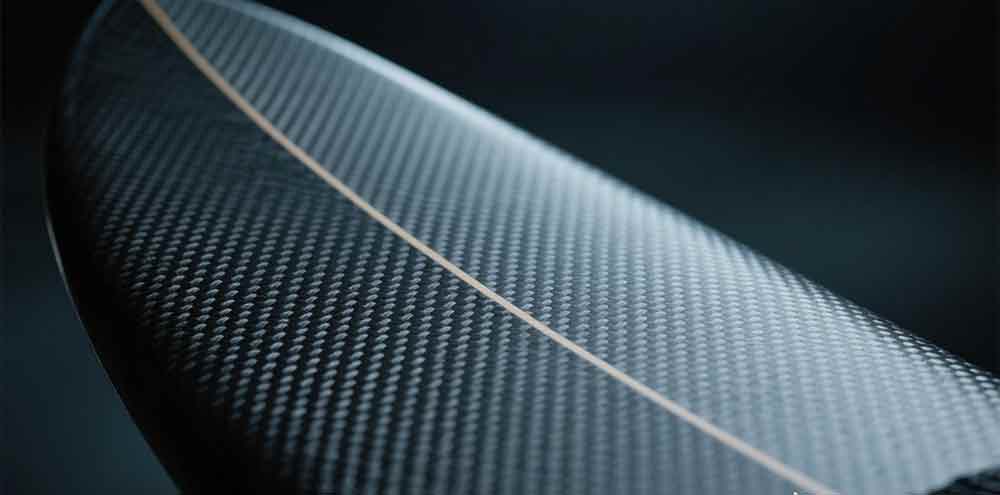

Foam surfboards differ significantly from other types of surfboards, such as fiberglass, carbon fiber, and epoxy boards, in several key ways for your reference:

- Construction: The primary difference is in the construction. Foam surfboards have a soft foam deck, while other surfboards typically have a hard shell made of fiberglass or epoxy resin.

- Buoyancy and Stability: Foam surfboards offer greater buoyancy and stability, making them ideal for beginners. In contrast, other surfboards may require more skill to balance on and ride effectively.

- Performance: Foam surfboards are generally less maneuverable and slower than their hard-shell counterparts. High-performance surfers prefer fiberglass and epoxy boards for their speed and responsiveness.

- Durability: Foam surfboards are known for their durability and ability to withstand heavy use and accidental bumps and dings. They are less likely to sustain severe damage compared to more fragile fiberglass boards.

- Weight: Foam surfboards are typically heavier than fiberglass or epoxy boards, which can affect maneuverability and ease of transportation.

The Disadvantages of Foam Surf Board

While foam surfboards offer numerous advantages, such as stability and safety, they also come with some disadvantages. It’s important to be aware of these drawbacks to make an informed choice when selecting a surfboard.

- Limited Performance: Foam surfboards are not designed for high-performance surfing. They lack the speed, responsiveness, and maneuverability of traditional fiberglass or epoxy surfboards. Advanced surfers seeking to perform more challenging maneuvers may find foam boards limiting.

- Lower Durability in Heavy Waves: Foam surfboards can be less durable when subjected to heavy waves and challenging surf conditions. The soft foam deck may be prone to damage in larger, more powerful surf, including dings, tears, or delamination.

- Weight: Foam surfboards tend to be heavier than their hard-shell counterparts. This extra weight can make paddling more tiring and affect maneuverability, especially for smaller riders or in larger waves.

- Difficulty in Duck Diving: Duck diving, the technique used to pass under oncoming waves, can be more challenging with foam surfboards due to their buoyancy. This can make it harder to navigate through breaking waves, particularly for intermediate and advanced surfers.

- Performance Plateau: As surfers progress in skill and experience, they may find that foam surfboards no longer challenge them. This can result in a plateau in skill development and the need to transition to a more advanced board for continued improvement.

- Tracking and Control: Foam surfboards may not track as well as other types of surfboards, making it more challenging to maintain a straight line while paddling. This can lead to less efficient paddling and slower wave-catching abilities.

- Limited Wave Range: While foam surfboards are suitable for smaller and slower waves, they may struggle to perform in larger and more powerful surf conditions. Surfers who aspire to tackle bigger waves may need to invest in a different type of surfboard.

- Style Limitations: Foam surfboards have a distinct look and feel. Some surfers may prefer the traditional appearance and aesthetics of hard-shell surfboards and find foam boards less appealing in terms of style.

- Environmental Concerns: Many foam surfboards are made from materials that are less environmentally friendly than traditional surfboards. The foam cores may not be as sustainable, and the disposal of damaged foam boards can contribute to waste problems.

- Cost Over Time: While foam surfboards are often more affordable upfront, they may require more frequent replacement or repairs compared to high-quality fiberglass or epoxy surfboards. This can result in long-term costs that offset the initial savings.

If you are interested in hard surfboard, welcome to click the link to see.

How to Repair Foam Surfboards

Despite their durability, foam surfboards can still sustain damage over time. Here’s a step-by-step guide on how to repair common issues with foam surfboards:

Materials Needed:

- Epoxy resin

- Fiberglass cloth

- Sandpaper

- Utility knife

- Mixing cups and sticks

- Masking tape

- Wax paper

- Disposable gloves

Repair Steps:

- Prepare the damaged area: Use the utility knife to remove any loose or damaged foam around the area that needs repair. Clean the surface thoroughly to ensure proper adhesion.

- Cut a fiberglass patch: Cut a piece of fiberglass cloth that is slightly larger than the damaged area. Ensure the edges are smooth.

- Mix epoxy resin: Follow the manufacturer’s instructions to mix the epoxy resin and hardener in a mixing cup. Wear disposable gloves for safety.

- Apply epoxy resin: Use a brush or spreader to apply a thin layer of epoxy resin onto the damaged area. Place the fiberglass patch over the wet resin, ensuring it covers the damaged section completely.

- Wet out the fiberglass: Carefully saturate the fiberglass cloth with epoxy resin, using the brush or spreader. Ensure there are no air bubbles trapped beneath the patch.

- Smooth and reinforce: Use a piece of wax paper over the fiberglass patch and press down firmly to smooth out any wrinkles and ensure proper adhesion. You can also add additional layers of fiberglass and resin for reinforcement, if needed.

- Cure and sand: Allow the repair to cure according to the epoxy resin manufacturer’s instructions. Once cured, sand the repaired area smooth with sandpaper.

- Finish: After sanding, the repaired area can be finished with surfboard wax to match the rest of the board’s surface.

Where to Buy a Foam Surfboard

Now that you’re ready to embrace the world of foam surfboards, you may be wondering where to find one. Here are some popular options for purchasing foam surfboards:

- Local Surf Shops: Visit your local surf shops, where you can browse a selection of foam surfboards and get personalized advice from knowledgeable staff. They can help you choose the right size and shape for your needs.

- Online Retailers: Numerous online retailers specialize in surfboards and offer a wide range of foam surf boards. Websites like SurfStitch, The Surfboard Warehouse, and evo have extensive selections and often provide customer reviews to help you make an informed choice.

- Surfboard Manufacturers: Consider buying directly from surfboard manufacturers or their official websites. Many well-known brands, such as Catch Surf and Wave Bandit, offer their foam surfboards for sale on their websites.

- Secondhand Market: You can also explore the secondhand market for foam surfboards. Websites like Craigslist, eBay, or local surfboard forums may have listings from individuals looking to sell their used boards.

- Surfboard Rental Shops: Some surfboard rental shops sell their used foam surfboards at the end of the season. These boards are often well-maintained and may offer a more budget-friendly option.

- Surfboard Expos and Events: Attend surfboard expos or events in your area, as these often feature surfboard vendors, including those selling foam surfboards. It’s a great opportunity to see the boards in person and talk to experts.

- Surf Schools: Surf schools sometimes sell their older foam surfboards to make room for new inventory. Check with local surf schools to see if they have any boards available for sale.

When purchasing a foam surfboard, consider factors such as size, shape, and volume to ensure it suits your skill level and intended use. If you’re unsure, don’t hesitate to seek advice from experienced surfers or professionals at surf shops.

Conclusion

Foam surfboards are an excellent choice for surfers of all levels, offering safety, durability, and versatility. Whether you’re a beginner learning to ride your first wave, a surf school instructor, or a seasoned surfer looking for a fun and relaxing ride, foam surfboards have something to offer.

Maintaining your foam surfboard is essential for its longevity, and proper storage and timely repairs are key. By following the steps outlined in this guide, you can ensure that your foam surfboard continues to provide you with countless hours of enjoyment on the waves.

While foam surfboards may differ from other types of surfboards in terms of construction and performance, they have their own unique charm and advantages. Their forgiving nature and stability make them an excellent choice for those starting their surfing journey.

To find the perfect foam surfboard for your needs, explore local surf shops, online retailers, surfboard manufacturers, the secondhand market, and even surfboard expos. With the right foam surfboard, you’ll be well on your way to mastering the art of surfing and experiencing the pure joy of riding the waves.