Twin Tip Kiteboard

This is a Twin Tip Kiteboard made of paulownia wood core, carbon fiber or glass fiber layup, ABS plastic reinforcement sidewalls, etc, which is processed by CNC and mold pressing technology. The kite surfing board produced like that will have a great performance for the characteristics, such as the accurate outline, strong toughness, and good FLEXF. It allows riders to ride equally well in both directions without switching foot positions. This makes it the most popular style of board for freestyle, freeride, and beginner riders.

Twin Tip Kiteboard Specification

- Board Type: Twin Tip Surfboard

- Core Material: Paulownia wood

- Layup: fiberglass or carbon fiber

- Reinforcement: ABS plastic

- Manufacturing Process: Molding & CNC

- Sample: Available

- Customized Design: Yes

- As a composite surfing manufacturer, we can also produce the foilboards, wakeboards, etc. Welcome to contact us for more details.

Kitesurfing Board Details

The P5 Twin Tip Kiteboard is engineered for smooth, balanced riding in both directions, making it ideal for freestyle and freeride kiteboarding. Featuring a CNC-machined paulownia wood core with ABS sidewalls, this board delivers an excellent combination of flex, durability, and lightweight performance.

Key Features:

-

Core: Paulownia wood, CNC precision cut, with ABS plastic reinforcement for added strength and edge durability.

-

Layup: Press-molded construction with customizable options in fiberglass or carbon fiber, finished with a protective top sheet.

-

Fin System: Pre-drilled dual-screw holes and foot strap inserts for easy setup and secure fit.

-

Design: Symmetrical shape allows effortless switch riding and smooth transitions.

Perfect for riders seeking responsive control, pop, and comfort underfoot, the P5 is built to perform across a variety of water conditions.

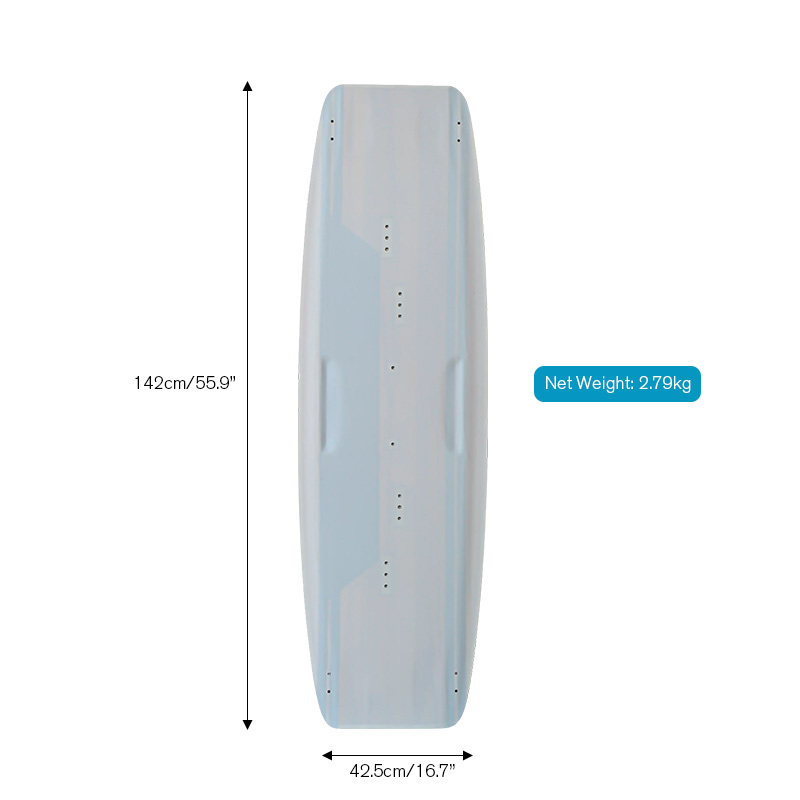

Twin Tip Kiteboard Size

Size: 142cm/55.9”*42.5cm/16.7”

Weight: 2.79kg

What customized service can we provide for this kite surfboard?

- Core material

- Layup

- Topsheet

- LOGO & board pattern design

Besides, if you have your design for the board’s shape, we can also provide the OEM service. For the production process, we can provide hand-made, mold pressing, and autoclaving.