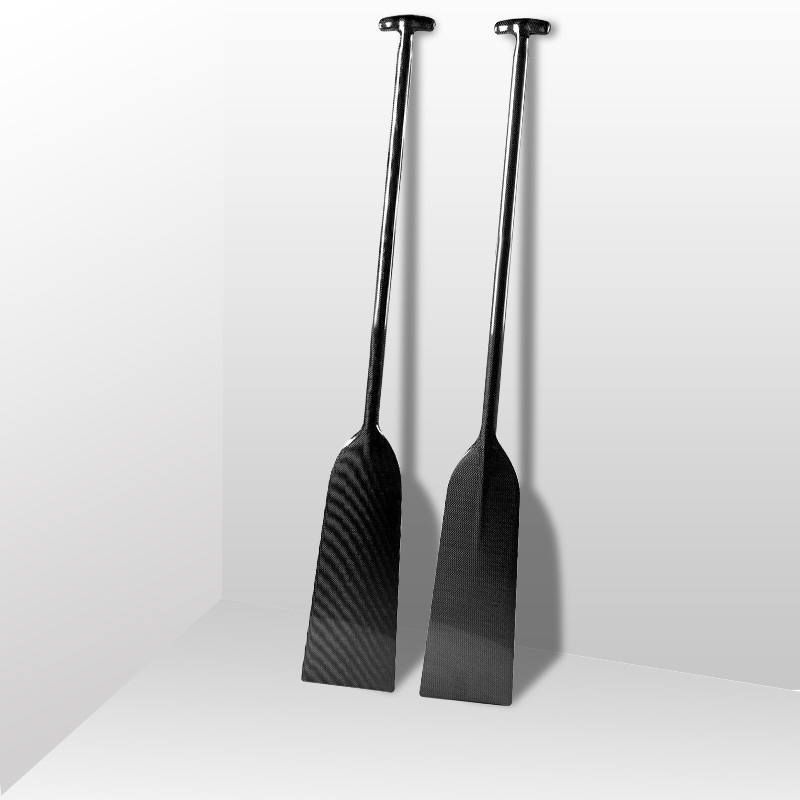

1 Piece Carbon Dragon Boat Oar

This high-performance carbon dragon boat oar is crafted entirely from lightweight, durable carbon fiber, designed for competitive and recreational dragon boat paddling. The one-piece construction ensures optimal stiffness, strength, and power transfer with every stroke, offering superior control and responsiveness on the water. Welcome to contact us to get the wholesale price.

Carbon Dragon Boat Oar Specification

- Section Type: One Piece Fixed Paddle

- Size: 113cm or 120cm/123cm/125cm

- Blade Size: 16.5*48cm or 20*48cm

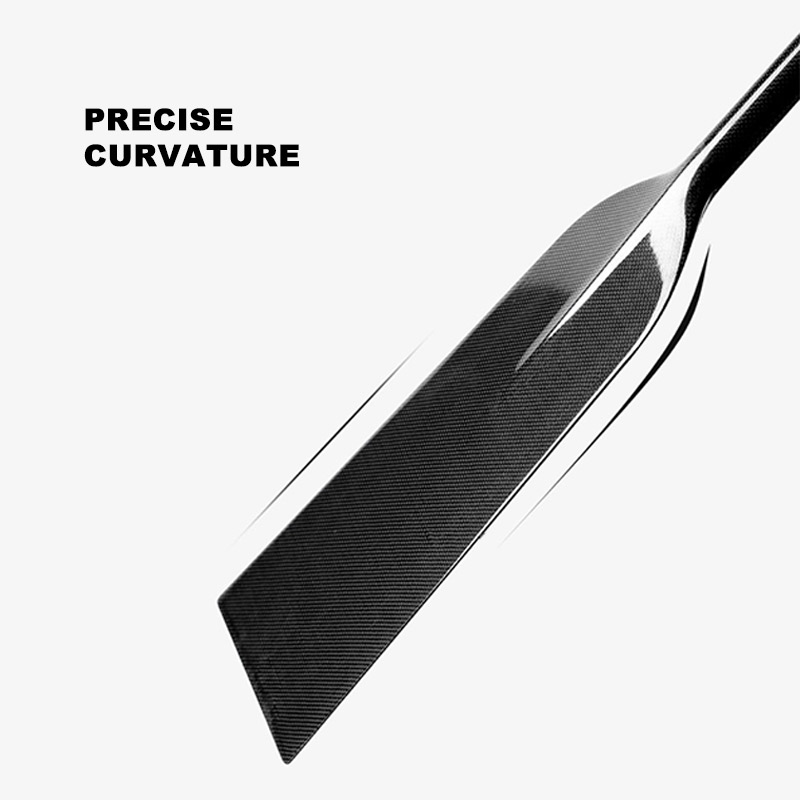

- Blade Type: Dihedral blade paddle or Flat blade paddle

- Material: Carbon Fiber Composite

- Weight: 300-360g

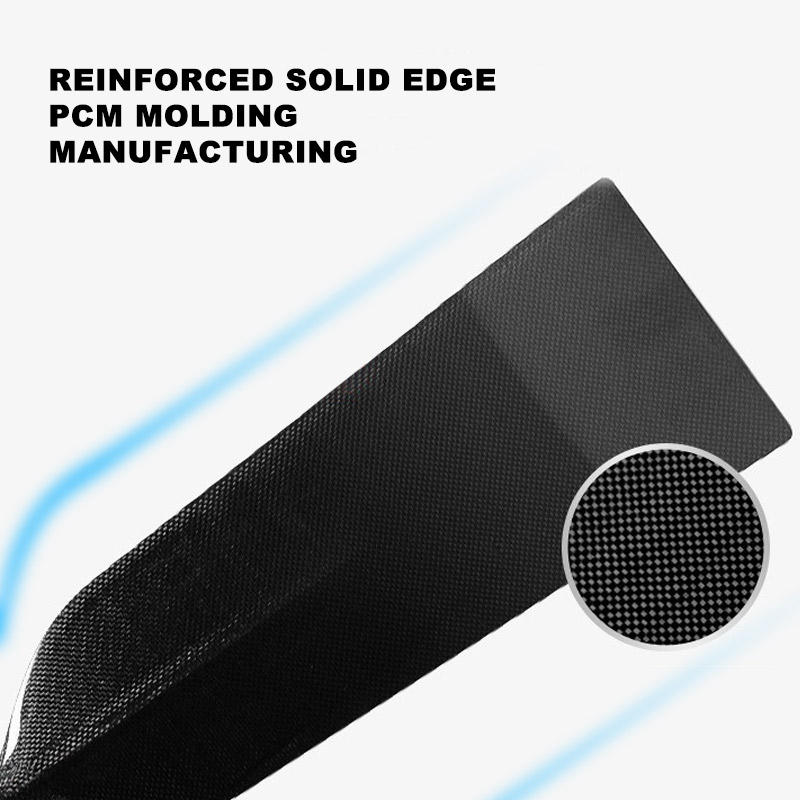

- Manufacturing Process: PCM molding

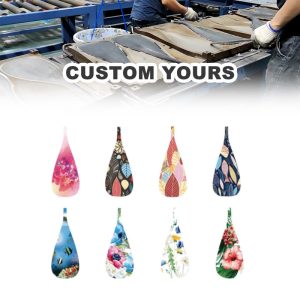

- Customized: Yes

- Wholesale Price: Send Us an Inquiry

Carbon Dragon Boat Paddle Details

Carbon Dragon Boat Oar Features

- Blade, shaft, and handle are made of carbon fiber, foam core, and epoxy composite for maximum durability and minimum weight, typically 300g to 360g.

- Eliminates weak points found in adjustable or two-piece paddles; ensures a solid, seamless feel and improved energy transfer.

- Ergonomically T-shaped handle for a secure and comfortable grip, even in wet conditions.

- Available in different finishes for aesthetic preference and reduced surface drag.

- Our dragon boat oar provides high stiffness to maximize stroke power and minimize energy loss. A dihedral blade paddle or a flat blade paddle is an option.

- Protects the paddle from prolonged sun exposure and water damage.

Paddle Size

Size: 113cm or 120cm/123cm/125cm

Blade Size: 16.5*48cm or 20*48cm

Customize Dragonboat Paddle

At our surfing factory, we specialize in producing high-performance, custom carbon fiber dragon boat oars using PCM (Prepreg Compression Molding) technology. This process ensures maximum precision, strength, and consistency for both professional athletes and teams seeking top-tier equipment. Here’s how we bring your custom paddle to life:

1. Client Consultation & Requirements

We begin with a detailed consultation to understand your specific needs:

-

Preferred blade shape (e.g., dihedral or flat)

-

Shaft stiffness level

-

Handle type (T-grip or palm grip)

-

Length and weight requirements

-

Custom branding, logos, or colors

2. Design & Technical Drawings

Our engineering team creates a custom paddle design based on IDBF specifications (if needed), incorporating all requested features. CAD modeling ensures structural integrity and ergonomic performance.

3. Prepreg Carbon Fiber Preparation

We use aerospace-grade pre-impregnated (prepreg) carbon fiber sheets, which are pre-coated with resin to ensure precise resin content and uniform quality.

4. Mold Setup (PCM Molding)

-

Molds for the blade, shaft, and handle are pre-heated and prepared.

-

The prepreg carbon fiber is hand-laid into the molds with extreme care for fiber alignment.

-

The molds are then closed under high temperature and pressure using PCM (Prepreg Compression Molding), ensuring consistent thickness, flawless surface finish, and structural strength.

5. Curing & Demolding

The paddle components are cured within the closed molds under precise conditions. Once cured, the parts are removed with minimal post-processing needed due to the clean finish provided by PCM.

6. Assembly & Finishing

-

The blade, shaft, and handle are bonded and aligned precisely.

-

Custom logos, graphics, or team colors are added using decals or water transfer printing.

-

A UV-resistant clear coat is applied for protection and durability.

7. Quality Control

Each paddle undergoes strict quality checks:

-

Dimensional accuracy

-

Surface finish

-

Weight balance

-

Strength testing (if applicable)

8. Packaging & Delivery

The finished dragon boat oars are securely packaged and shipped globally with optional tracking and express service.